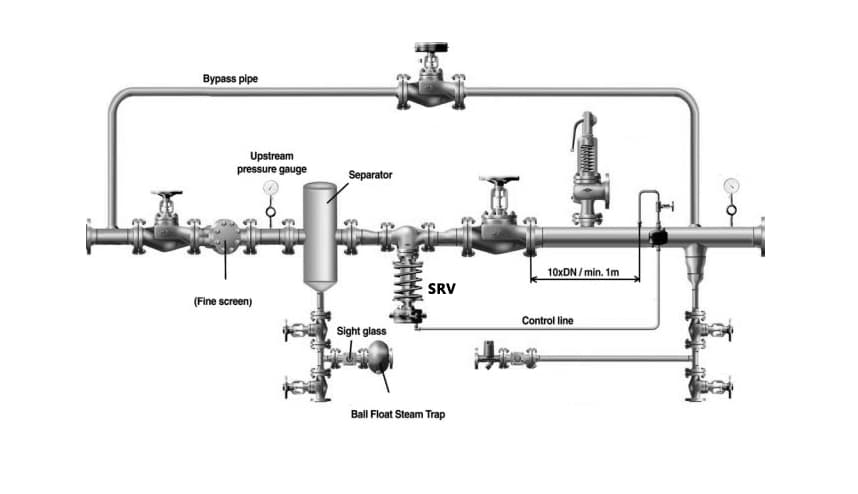

A pressure relief valve sized to relieve the maximum inlet supply pressure of the station to an acceptable open site drain in the event of PRV diaphragm failure and the resulting discharge of water from the safety valve. Requirements for Steam Pressure Reducing Valve Stations it is not inclusive to the control valve and encompasses the general requirements for the PRV station.

Pressure Reducing Station Volfram Systems

PART 2 - GENERAL UNIVERSITY DESIGN REQUIREMENTS 21 MINIMUM DESIGN REQUIREMENTS A.

. Bypass lines are not required. What is Steam Pressure Reduction. PRESSURE REDUCING STATION DESIGN GUIDELINES PRESSURE REDUCING STATION GENERAL SPECIFICATION I.

When ratio of specific volume of steam outlet to inlet is no greater than 3 to 1. The correct design and component selection of steam pressure reducing valve stations will highly extend the operational life of the steam system. Within practical limits pressure-reducing valves PRVs will adjust the pressure at lower levels to the.

YALE OFFICE OF FACILITIES PROCEDURE MANUAL Chapter. When only one reduced steam. Pressure Reducing Valves.

Pressure reducing valves shall be selected and specified around a Spence Type E. The steam pressure-reducing valve station an indispensable part of a steam system. When to use single stage regulator.

All steam equipment have a MAWP - maximum allowable working pressure. The total steam capacities must be equal to or greater than the maximum steam flow to the system to ensure they never exceed the maximum steam pressure. It is sized using special software to ensure appropriate parameters as per design conditions.

Pressure reducing stations 2D CAD application drawings to help you plan and design your steam system. When load turndown requirement is generally no greater than 101. The standard applies to both Building and Utility Systems.

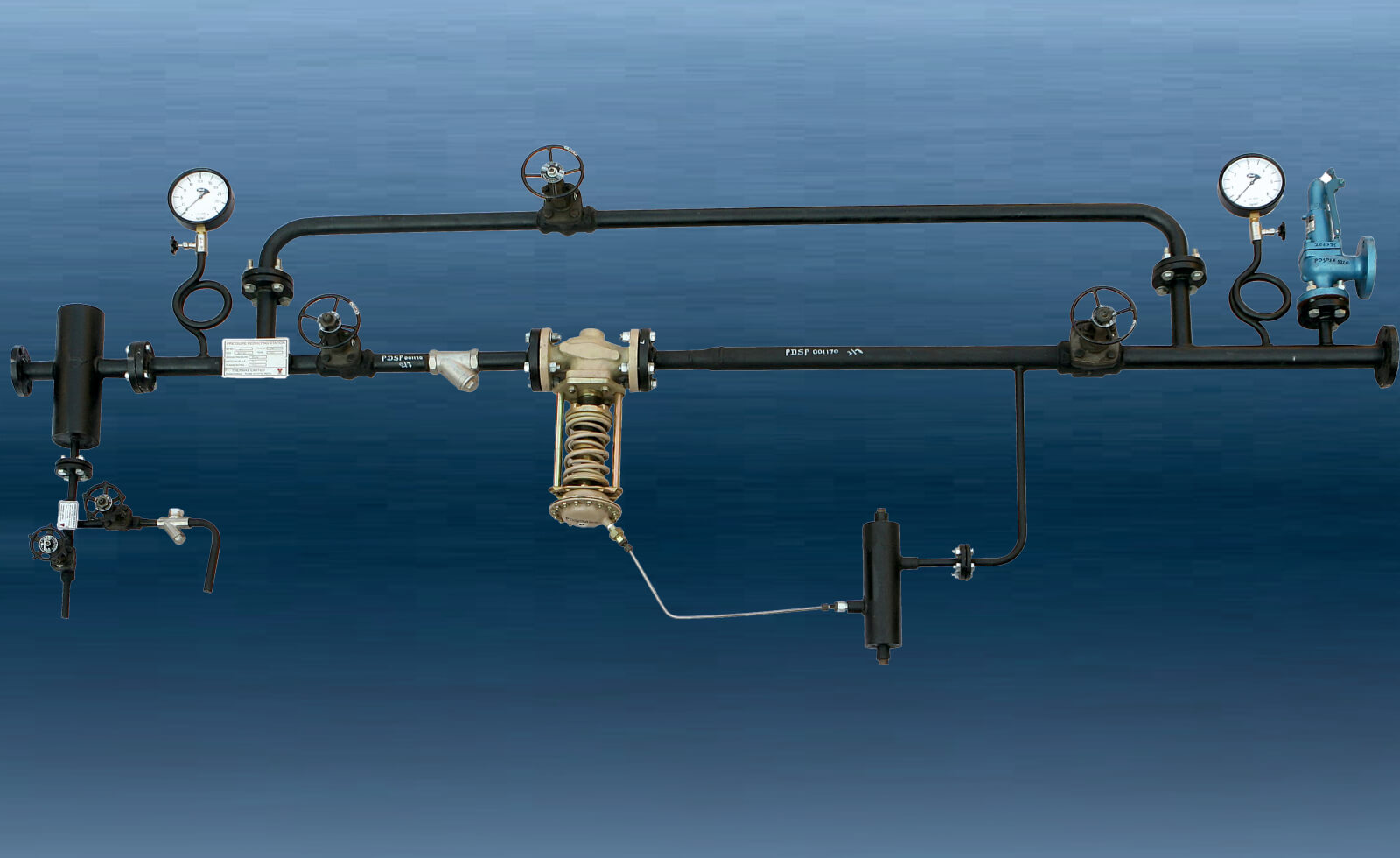

About us Global Locations Careers Learn about steam Resources and Design Tools Contact Head Office. Thermax Pressure Reducing Station TPRS is a prefabricated ready to assemble module comprises of control valves isolation valves pipes and fittings intended to reduce steam pressure to designed conditions. ECONOMIC BENEFITS OF PRESSURE REDUCTION.

Two Stage Pressure Reducing Valve Station. It plays a critical role by providing the correct steam pressure to the process application in the process plant. Steam and reduce pressure upstream of any items of plant designed to operate at a lower pressure.

SINGLE STAGE PRESSURE REGULATOR 1. The first PRV will reduce the high-pressure steam to an intermediate pressure. The Steam Pressure Reducing Station.

Select PRV station as follows. The Steam Pressure-Reducing Station SPRS Safety and Energy Efficiency Improvement Project which is under the CPI program focuses on maintaining and upgrading SPRSs that are part of the ORNL steam distribution network. LP steam has higher latent heat and can tend to reduce the amount of steam produced by the boiler ie higher efficiencies.

Pressure drop Δ P no greater than 150 psig. Setting on the boiler plant master control. A maximum Δ P of 100 psig per valve is recommended as higher pressure drops shorten plug and.

The second PRV will reduce the intermediate pressure to the final desired pressure. This steam pipe network transports steam produced at the ORNL steam plant to many buildings in the main campus site. Follow the Spence Regulator Designers guide for sizing and layout of PRV stations.

Initially this pressure depends on the nominal pressure of the section of the system dow nstream of the pressure reducing station and on the. Pressure Reducing Stations Date. The set points are below the steam system maximum design pressure.

A steam pressure-reducing valve station often employs a pneumatic control valve or a regulating valvesometimes called a pressure-reducing valve as. Design and Flow Concept Page 5 from 7 September 2005 Diagram 1. New York Engineers under its prestigious reputation in Chicago guarantees to offer pressure reducing valves with long-lasting operational life of at least 6 years.

Steam pressure reduction affects mainly the high pressure part of the steam system. Pressure reducer - for saturated steam With safety valves the first step is to define the set pressure. Business Pressure reducing stations PRS is the arrangement of certain valves which is used to provide desired steam pressure at users end.

Office of Facilities CC. The design of the Main Steam Pressure Reducing Stations in buildings that are being supplied steam from a central steam generating plant or other high pressure steam generating source must take into consideration load characteristics rangeability noise safety reliability long- term maintenance costs and overall control performance. Pressure gauges on the inlet and outlet of the station and between staged valves in series.

Steam pressure reduction is the lowering of the steam pressure at the boiler plant by means of the pressure. 01 - Yale Design Standard Division. Project Folder Page 4 of 10 Therefore if the isolation valve is closed and the PRV opens the piping could experience the inlet steam pressure.

All pressure reducing valve stations serving an entire building will have 2 pressure reducing valves sized at 13 and 23 of the total load. Steam coming from the Boiler through the steam line enters the PRS at a higher pressure and leaves the PRS at reduced specified pressure in this the flow of the steam remains constant.

Steam Pressure Reducing Stations Industrial Controls

Steam Pressure Reducing Stations Industrial Controls

3 Typical Systems Of Steam Pressure Reducing Station Thinktank

Pressure Reducing Station Youtube

0 comments

Post a Comment